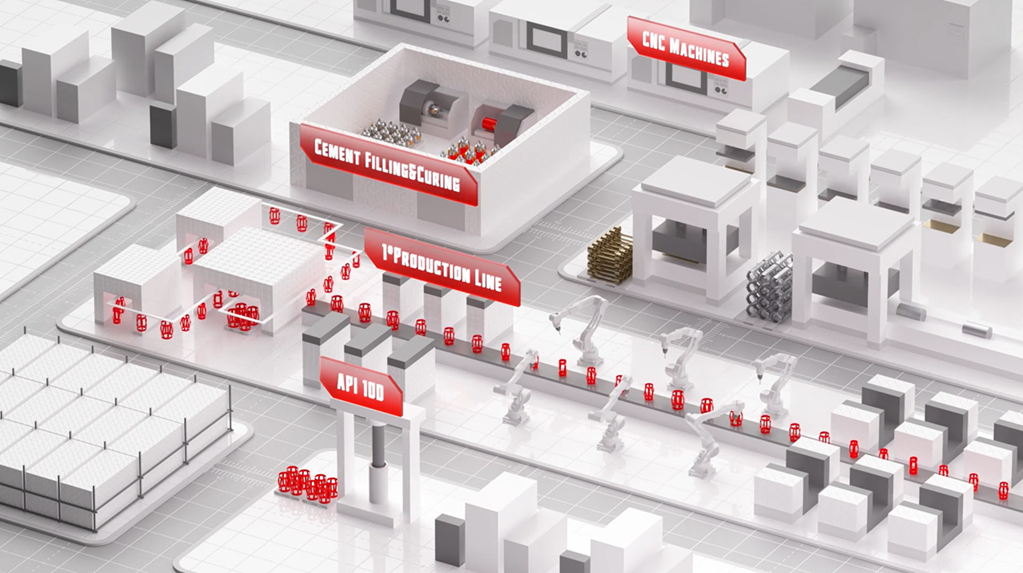

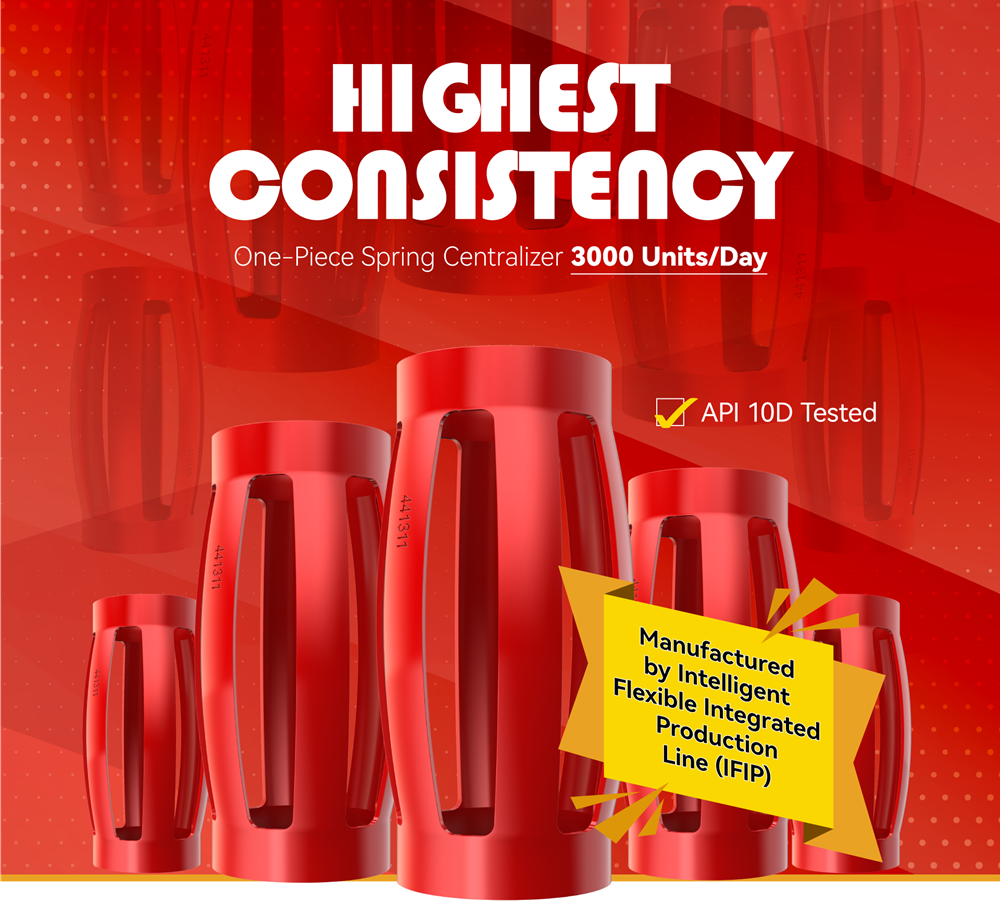

At Newland Oiltools, we believe that speed only matters when it is matched by uncompromising quality and consistency. By incorporating automated manufacturing machines, customized software systems, and dedicated self-patented production technologies, our Intelligent Flexible Integrated Production line achieves the complete modernization of centralizer & stop collar production.

Designed and built entirely in-house, IFIP enables production of up to 3,000 one-piece bow-spring centralizers every eight hours, while every stage of manufacturing is digitally monitored for accuracy. Because of the automated production technology and systems, this production capacity can be achieved only with ten to fifteen workers, no sophisticated jobs required. IFIP can be used for manufacturing all different kinds of centralizers, ranging from bow spring to rigid solid, as well as various stop collars. From raw material preparation through forming, welding, and final inspection, each unit is produced to specifications that consistently exceed API 10D standards, ensuring the mechanical properties of every centralizer remain stable in even the harshest oilfield environments.

With independent intellectual property, industry-first patents, and the mass application of intelligent manufacturing technologies, IFIP redefines what efficient, high-quality centralizer production means. It is more than an upgrade; it is a complete re-imagination of scale, consistency, and reliability—proof that Newland Oiltools is setting new global benchmarks for automation, precision, and trust.