At Newland Oiltools, we recognize that reliable downhole performance begins with rigorous, verifiable testing. Our in-house Test Service was created to provide customers with complete confidence that every product—whether float equipment, centralizer, or cable protector—meets or exceeds the most demanding global standards. By combining proprietary test systems with advanced monitoring technology, we ensure that each tool we produce can withstand the extreme pressures, temperatures, and abrasive conditions of the oilfield.

It contains a full suite of mud-circulation test equipment capable of simulating the harshest well conditions. Using fluid media containing mud and sand, these systems continuously monitor pressure, flow, and temperature over 24-hour cycles to replicate real downhole environments. This enables testing to the latest API 10F specification as well as to customer-specific requirements, allowing precise prediction of product performance long before deployment.

With all relevant testing equipment and software system developed fully in-house and patented to us. The test center is able to perform centralizer starting/running force test as well as restoring force test, with computer software system used for continuous and accurate data acquisition. Digital, full-process monitoring captures every performance parameter in real time, while full-scale simulated boreholes and casings allow testing that goes well beyond API 10D standards.

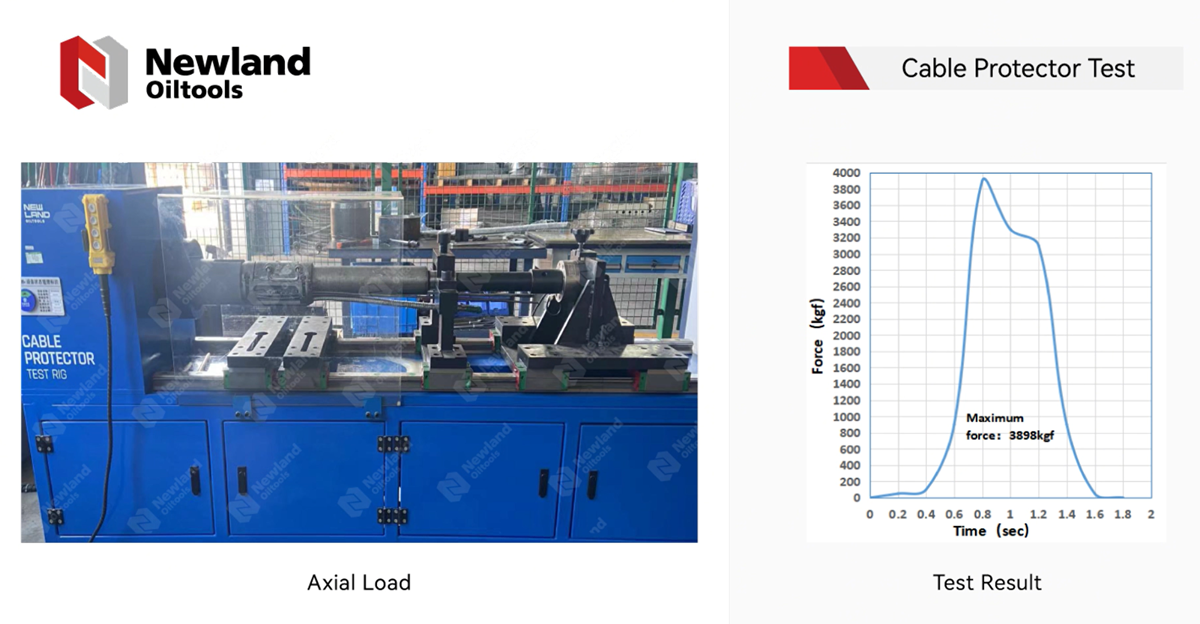

The application of cable protectors involvescoordination between multiple factors: the protectors themselves, tubing through couplings, casings, and cables. These require scientific and rigorous testing for authentic verification. To this end, Newland has independently developed a fully digitally controlled comprehensive performance testing platform with independent intellectual property rights, specifically for testing cable protectors. It can conduct the following five tests on cable protectors:

1. Abrasion resistance test of cable protector materials

2. Holding force test of cable

3. Anti-rotation torque test of cable protectors

4. Axial load-bearing capacity test of cable protectors

5. Lateral load-bearing capacity test of cable protectors

Every batch of cable protectors undergoes stringent holding-force and load testing, a practice we have maintained for more than 18 years to guarantee safe cable delivery to target depths.

From API-compliant verification to custom stress tests, Newland’s Test Service provides the data and assurance operators need to reduce risk and optimize well integrity. By pairing industry-leading equipment with a culture of continuous innovation and commitment to quality, we deliver more than certification—we deliver proven reliability for the world’s most challenging wells.